09

2020-12

Flash Converting Furnace Modification Project for Rio Tinto Kennecott Ultah Copper Smelter in the USA Put into Operation Successfully

Recently, the flash converting furnace modification project for Rio Tinto Kennecott Ultah Copper Smelter designed by China Nerin was put into operation successfully with qualified blister produced. All the technical indicators of the flash converting furnace (FCF) are better than those before the modification. The design targets were met and the project was smoothly accepted by Rio Tinto.

Kennecott Ultah Copper Smelter was the first in the world to adopt the process of flash smelting and flash converting (“double flash” in short) and was also the benchmark when China decided to introduce the “double flash” technology. To optimize the plant and improve its efficiency, China Nerin made a comprehensive technical diagnosis for Kennecott Ultah Copper Smelter in 2016 and presented an integrated solution. The flash converting system modification project was the first to be implemented and one of the keys was to solve problems such as matte segregation and high fault frequency of the matte burner. China Nerin worked closely with Yanggu Xiangguang Copper on the project and replaced the central jet-distribution burner, a patented technology jointly developed and owned by Outotec in Finland and Kennecott Ultah Copper Smelter in the USA, with a cyclone burner whose intellectual property right is independent owned by Chinese companies. After the replacement, the phenomena of matte segregation and overheat in the reaction shaft are eradicated, and the maintenance frequency becomes greatly lower and the FCF oxygen utilization and availability are both obviously increased.

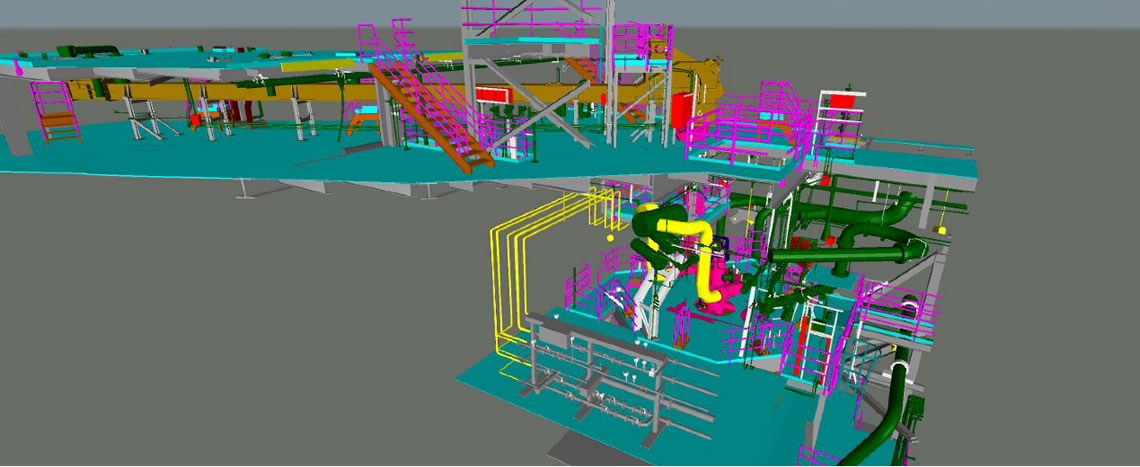

China Nerin adopted advanced design concepts and conducted conceptual design, feasibility study and detailed engineering of the project in full 3D design method. Since it’s a smelter with history, many drawings and data were not available. To overcome such difficulties, China Nerin’s team made visits to the project site, thoroughly analyzed problems in the existing operation system, and provided a reasonable option for the modification project, which was highly recognized by the owner. Due to the Covid-19, the team couldn’t make it on the site. For the commissioning, the team overcame the difficulty of time difference and guided the owner to operate and control the new burner through video meeting. It also effectively guaranteed smooth operation of the project.

The success of the project means the success of the first export of Chinese key copper smelting technology and equipment to the North America after many years of import. It is definitively a milestone in the development of Chinese copper smelting technology because it’s not only the first export of such but also an export to a developed country. It indicates China's copper smelting technology as a whole is now in the international leading level.

Smelting Plant of Kennecott Ultah Copper Smelter

3D Design Model